Clinical Research Report

Objectives

To investigate the effect of OceanFeedTM Poultry seaweed blend (OFP) on growth performance and breast meat yield in commercial broilers.

Summary of findings:

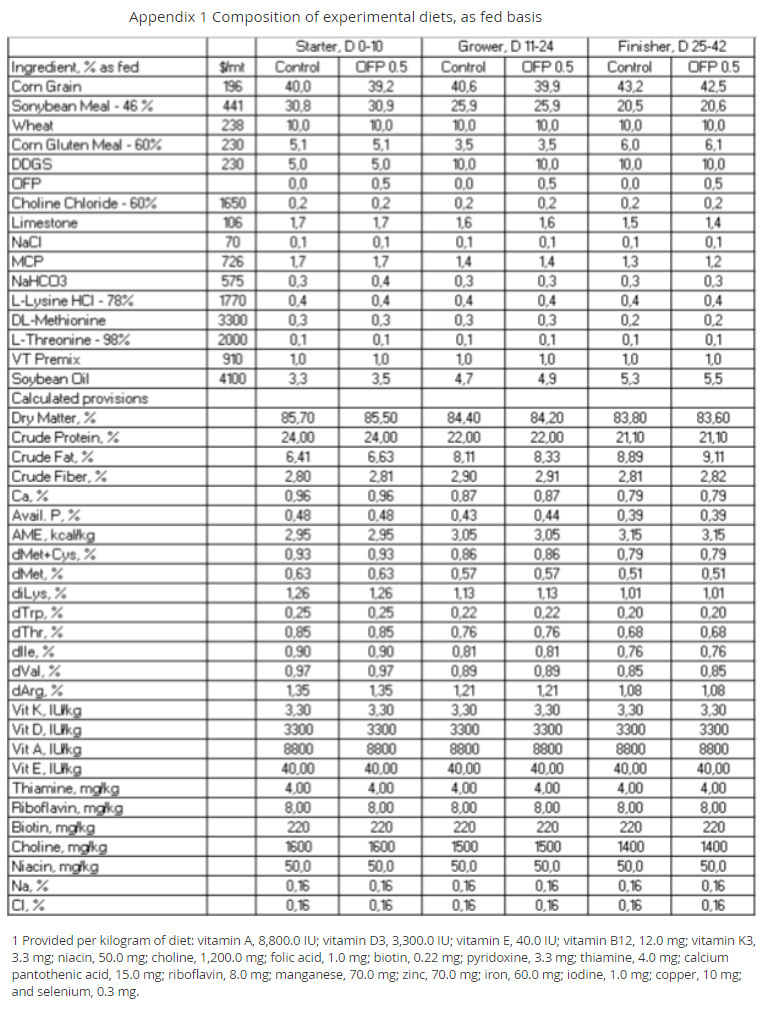

- In starter phase, OFP at 0.5% OFP inclusion improved body weight (BW), body weight gain (BWG) and Feed conversion ratio (FCR). Response to OFP in the grower phase was similar to the starter phase with improvements in average daily feed intake (ADFI), BWG and FCR. In the finisher phase only BWG was improved.

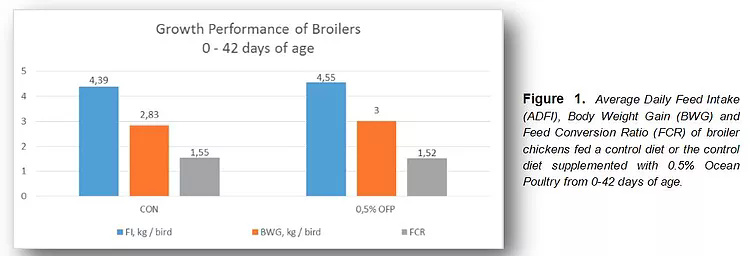

- Overall (d 0-42), final BW (d 42) of birds fed the control plus 0.5, was heavier than those fed the Control diet by 166 grams.

- Overall, birds fed 0.5% OFP had 2.2% better FCR relative to the control birds.

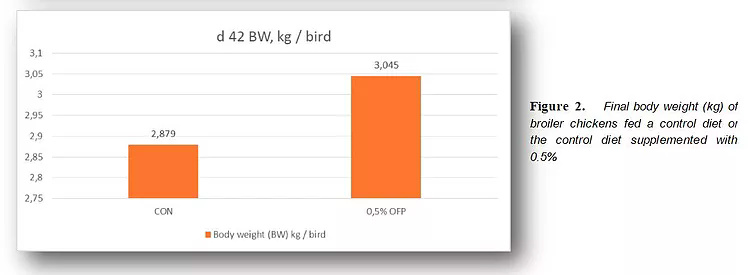

- Birds fed 0.5% OFP had 9.2% higher breast yield relative to the control birds.

- Mortality was reduced in birds fed the OFP diet compared to controls (1.9 vs 3.2%)

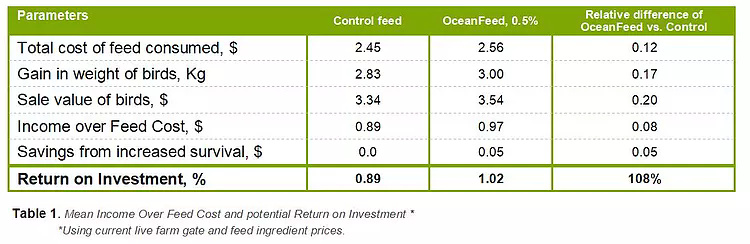

- Due to improved performance and survival rate, OceanFeedTM Poultry provided a return of investment of 108%

Methods:

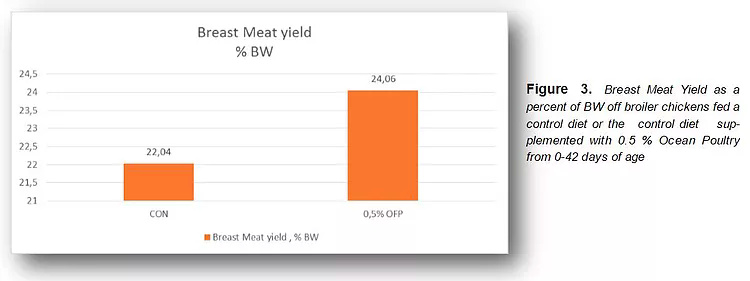

- Two (2) dietary treatments: Control and OFP dose at 0.5% of the feed were tested (appendix 1). Diets were formulated as a 3-phase feeding program: Starter; d 0-10, Grower: d 11-24, and Finisher; d 25-42. Diets were corn-soy-based with no prebiotic, probiotic, anticoccidial or antimicrobial growth promoting substances. The starter was prepared in crumble form whereas the grower and finisher were prepared in pellet form. The temperature during feed processing was 65-70˚C and steam pressure of 30 psi.

- A total of 432 d old (male) Ross x Ross 708 broiler chicks were procured from a commercial hatchery, weighed and allocated to 24 floor pens (18 birds per pen) with fresh wood shavings. The pens were housed in four separate environmentally controlled rooms with 12 pens each. The room temperature was set to breeder recommendation of 32°C on d 0 and gradually decreased to 27°C by d 17 (Aviagen, 2014). Birds were exposed to fluorescent lighting in a 23 hr of light (20+ lux) for the first 4 days and then a 16 light: 8 dark (10-15 lux) light cycle for the remainder of the experiment. The diets were allocated to 24 floor pens in a completely randomized block (room) design.

- Birds had free access to water via nipples and feed via feeders throughout the experiment. Body weight and feed intake was monitored at on d 0, 10, 24 and 42 for calculation of BWG and FCR. Mortalities were counted, and BW recorded for calculation of mortality adjusted FCR. One bird per pen was randomly selected, weighed and sacrificed at the end of the experiment for breast yield.

Data analysis:

Mortality adjusted FCR was calculated as: FCR Adjusted for mortality (AFCR = weight of feed consumed)/(weight gain of survivors + weight gain of mortalities). Breast yield was standardized for BW. Data were analyzed using the GLM procedure of SAS (SAS Institute 2016), with pen as the experimental unit. The model had diet as fixed effect and block (room) as variable effect. Significance was declared at P < 0.05.

“Due to improved performance and survival rate, Ocean Poultry provided a return of investment of 108%”

Conclusion

Conclusion

- Under the conditions of the present trial, OFP at 0.5% was sufficient for improving BWG, FCR and breast meat yield over the control birds fed a similar diet.

- Performance was improved by increasing the dose of OFP, but not significantly above birds consuming 0.5% OFP. Given the high health status of the facility, higher doses may be appropriate under more challenging environmental conditions.

- Mortality was improved by 40.6% (1.9% vs 3.2%) in the 0.5% OFP birds compared to control birds.

- Margin over feed cost was improved by $0.13 per bird with 0.5% OFP inclusion.

- Due to improved margin over feed costs and increased survival rate, the return on investment in OceanFeedTM Poultry was 108%